Paxlovid Intermediates: A Breakthrough in Antiviral Drug Manufacturing

The ongoing COVID-19 pandemic has presented an urgent need for effective antiviral treatments. As researchers around the world continue to explore various therapeutic options, one particular breakthrough has been the development of Paxlovid, a promising antiviral drug. Paxlovid has shown significant efficacy in combating the SARS-CoV-2 virus, providing hope for millions of people affected by the global health crisis. However, behind the success of Paxlovid lies the crucial role of Paxlovid intermediates manufacturers in the pharmaceutical industry.

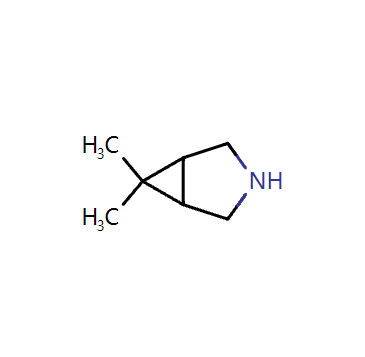

Paxlovid intermediates serve as key components in the synthesis of the final drug formulation. These intermediates are chemical compounds that undergo further processing to yield the active pharmaceutical ingredient (API) of Paxlovid. They play a critical role in ensuring the quality, purity, and efficacy of the final product. Without the expertise and precision of Paxlovid intermediates manufacturers, the production of this breakthrough antiviral drug would not be possible.

Manufacturing Paxlovid intermediates requires a combination of advanced chemical synthesis techniques, strict quality control measures, and adherence to regulatory standards. Specialized pharmaceutical companies equipped with state-of-the-art facilities and a team of highly skilled scientists and chemists undertake the complex task of producing these intermediates. Their expertise in organic synthesis, process optimization, and analytical techniques enables them to develop efficient and reliable manufacturing processes for Paxlovid intermediates.

The production of Paxlovid intermediates involves several stages, starting from the selection of appropriate starting materials and reagents. Through careful selection and evaluation, manufacturers ensure the safety and quality of the raw materials used. Once the starting materials are identified, they undergo a series of chemical reactions and purification steps to obtain the desired intermediate compounds. Each step is meticulously monitored and controlled to maintain the highest standards of quality and purity.

Quality control and assurance are paramount in the manufacturing of Paxlovid intermediates. Manufacturers employ rigorous analytical testing methods to verify the identity, purity, and potency of the intermediates at various stages of production. These tests include high-performance liquid chromatography (HPLC), gas chromatography (GC), and spectroscopic techniques, among others. By adhering to stringent quality control protocols, Paxlovid intermediates manufacturers ensure that the final product meets the required specifications and regulatory standards.

The critical role of Paxlovid intermediates manufacturers in the production of this life-saving drug cannot be overstated. Their dedication to quality, expertise in chemical synthesis, and commitment to innovation contribute to the successful synthesis of Paxlovid. Through their efforts, the pharmaceutical industry can efficiently produce and distribute this antiviral drug to those in need, bringing hope and relief to individuals and communities affected by the COVID-19 pandemic.

In conclusion, Paxlovid intermediates manufacturers play a vital role in the production of the breakthrough antiviral drug Paxlovid. Their expertise and precision in chemical synthesis, quality control, and adherence to regulatory standards enable the efficient and reliable production of these key components. The development and availability of Paxlovid as an effective treatment option against SARS-CoV-2 are made possible through the dedication and commitment of Paxlovid intermediates manufacturers. To learn more about Paxlovid intermediates and the manufacturing process, click here.

223

0

0

Previous: Is HPMC natural or synthetic?

Next: None

Comments

All Comments (0)