What are the different types of mini ball valves?

Introduction:

In the vast realm of industrial valves, mini ball valves stand out as compact yet crucial components that play a pivotal role in controlling the flow of fluids and gases. These miniature wonders are designed for applications where space is limited, and precision is paramount. In this article, we will delve into the diverse world of mini ball valves, exploring their types, applications, and key features.

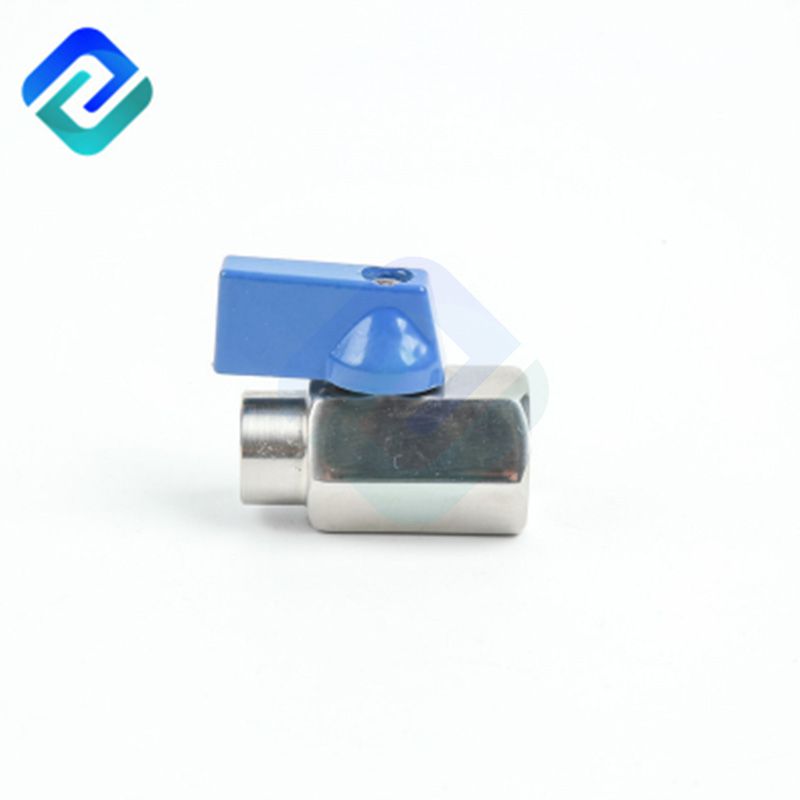

Standard Mini Ball Valves:

The standard mini ball valve is the fundamental building block of this category. These valves consist of a spherical disc with a hole bored through the center, allowing for precise control of fluid flow. The design is simple yet effective, making them suitable for a wide range of applications. Standard mini ball valves are commonly made from materials such as brass or stainless steel, providing durability and resistance to corrosion.

Reduced Bore Mini Ball Valves:

Reduced bore mini ball valves, also known as "reduced port" valves, have a smaller ball and opening compared to their standard counterparts. This design minimizes flow restrictions but sacrifices some flow capacity. Reduced bore mini ball valves are ideal for applications where space is at a premium, and the trade-off between size and flow capacity is acceptable. These valves find applications in industries such as HVAC, instrumentation, and pneumatic systems.

Full Bore Mini Ball Valves:

Contrary to reduced bore valves, full bore mini ball valves have a larger ball and opening, allowing for unrestricted flow. This design is preferred in applications where maximum flow capacity is critical, and space constraints are less of a concern. Full bore mini ball valves are commonly used in industrial processes, water treatment, and oil and gas applications.

Three-Way Mini Ball Valves:

Three-way mini ball valves, as the name suggests, have three ports and a T-shaped configuration. These valves enable the diversion of flow between two inlet ports to a single outlet or vice versa. The versatility of three-way mini ball valves makes them suitable for applications requiring the redirection of fluid or gas flows, such as in mixing applications or system bypasses.

Mini Ball Valves with Actuators:

To enhance precision and control, mini ball valves can be equipped with actuators, turning them into automated valves. Actuators, powered by electricity, pneumatic pressure, or other sources, allow for remote operation and control. These automated mini ball valves find applications in industries where precise and automated fluid control is essential, such as in chemical processing, pharmaceuticals, and water treatment.

Mini Ball Valves with Extended Stems:

Extended stem mini ball valves are designed with longer stems, making them suitable for applications where the valve is installed in hard-to-reach or concealed locations. The extended stem allows for easier operation of the valve without requiring direct access to the valve body. This type of mini ball valve is commonly employed in installations where space constraints demand creative solutions for valve placement.

Mini Ball Valves with Needle Valves:

In some applications where fine-tuned control of flow is critical, mini ball valves with integrated needle valves are employed. The addition of a needle valve allows for precise adjustment of flow rates, making these valves ideal for applications such as laboratory equipment, analytical instruments, and other systems where accuracy is paramount.

Conclusion:

Mini ball valves may be small in size, but their impact on fluid and gas control in various industries is substantial. The different types of mini ball valves cater to specific needs, offering solutions for applications ranging from standard to specialized. As technology continues to advance, these miniature marvels will likely evolve, providing even more efficient and tailored solutions for industries that depend on precise fluid and gas control. Understanding the diverse types of mini ball valves is crucial for engineers, designers, and professionals working in fields where precision, space constraints, and reliability are of utmost importance.

148

0

0

Comments

All Comments (0)