How often should cooling tower fill be replaced?

Cooling towers play a crucial role in industrial processes by efficiently removing excess heat from water-based systems. The fill, a key component of cooling towers, facilitates the exchange of heat between water and air. Over time, factors such as water quality, environmental conditions, and maintenance practices can impact the performance of cooling tower fill.

Understanding Cooling Tower Fill

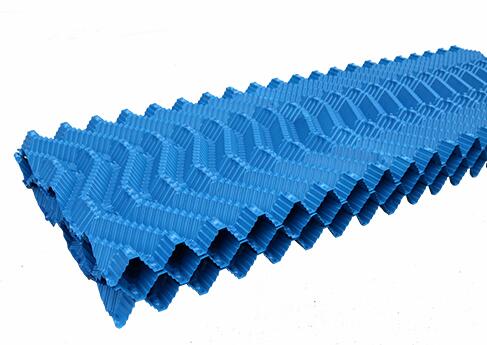

Cooling tower fill is the part of the tower that promotes the maximum contact between air and water. It consists of a series of sheets or modules with corrugated surfaces, creating a large surface area for the water to flow over. This increased surface area enhances the efficiency of heat transfer, making it a critical element in the cooling process.

Factors Influencing Replacement Frequency

1. Water Quality:

The quality of the water circulating through the cooling tower significantly impacts the lifespan of the fill. Water containing high levels of impurities, scale-forming minerals, or microbiological contaminants can accelerate the deterioration of the fill material.

2. Environmental Conditions:

External factors such as climate, temperature fluctuations, and exposure to sunlight can contribute to wear and tear. Extreme weather conditions, including high temperatures, heavy rainfall, and prolonged exposure to UV radiation, may accelerate the degradation of cooling tower fill.

3. Maintenance Practices:

Regular maintenance is crucial in extending the lifespan of cooling tower fill. Effective water treatment programs, routine cleaning, and preventive measures against scale formation or biological growth can contribute to the longevity of the fill material.

4. Material Composition:

Additional reading:Fiberglass Mesh Drywall Tape: Unveiling the Secrets to Seamless Walls

What is a sponge filter and how does it work?

Electric Dump Truck: Revolutionizing Construction Efficiencies

How to Prevent Corrosion in GFS Agricultural Water Tanks?

How to Choose the Best Fiberglass Mesh For Waterproofing?

How do I make PVC fire resistant?

What are the top 10 advantages of using pe tarpaulin canvas in your business?

The material composition of the cooling tower fill plays a pivotal role in its durability. Fill materials are commonly made of PVC (Polyvinyl Chloride) or other polymers. The quality and thickness of the material influence how well it withstands the harsh conditions within the cooling tower.

Signs that Cooling Tower Fill Needs Replacement

Reduced Heat Transfer Efficiency:

A noticeable decrease in the efficiency of heat transfer is an early indicator that the fill may be reaching the end of its effective lifespan. This can result in decreased cooling capacity and overall system performance.

Scale Buildup and Fouling:

Accumulation of scale or biological growth on the fill surfaces can impede water flow and reduce heat transfer efficiency. If routine maintenance does not address these issues, it may be a sign that replacement is necessary.

Physical Damage:

Physical damage to the fill, such as cracks, breaks, or significant deformities, can compromise its structural integrity. Damaged fill should be promptly replaced to prevent further deterioration.

Determining Replacement Frequency

There is no one-size-fits-all answer to how often cooling tower fill should be replaced, as it depends on a combination of the factors mentioned above. Regular inspection and monitoring of the cooling tower fill are essential. Conducting routine water quality analysis, assessing environmental conditions, and adhering to a proactive maintenance schedule can aid in determining the optimal replacement frequency.

Maintaining the efficiency of cooling tower fill is pivotal for the overall performance of cooling systems. While there is no fixed timeframe for replacement, a combination of factors such as water quality, environmental conditions, maintenance practices, and material composition should be considered. Regular inspections and a proactive approach to maintenance will contribute to the longevity of cooling tower fill and ensure the continued efficiency of industrial cooling processes.

Revolutionizing Building Industry: Rondy Fiberglass Mesh - How?

Ultimate Guide to Mosaic Fiberglass Mesh: Benefits, Uses & Installation Tips

Why Fiberglass Mesh is a Game Changer?

What are the benefits of a wood slat wall?

GFS Agricultural Water Storage Tanks: Enhancing Efficiency and Sustainability in Farming

How to Properly Maintain Your Vinyl Sports Flooring

Geogrid vs. Geotextile: Which Solution is Right for Soil Reinforcement?

138

0

0

Related Articles

-

Benefits of Belleville Washers

210

0

0

Comments

All Comments (0)