How Long Can a Diaphragm Pump Run Dry?

How Long Can a Diaphragm Pump Run Dry?

Diaphragm pumps are essential components in various industrial applications, known for their reliability and versatility. However, a common concern is their ability to operate without a liquid source, often referred to as running dry. While diaphragm pumps are designed to handle dry running to a certain extent, the duration and impact of running dry can vary based on factors such as pump type, materials, and operating conditions. In this article, we explore the concept of running a diaphragm pump dry, its potential consequences, and guidelines for safe operation.

Understanding Dry Running

Diaphragm Pumps and Their Operation

Diaphragm pumps are positive displacement pumps that use reciprocating motion to transfer fluids. They consist of a diaphragm that moves back and forth, creating a vacuum on one side and pressure on the other. This action allows the pump to draw in and expel fluids.

Dry Running

Dry running occurs when a diaphragm pump operates without any fluid to transfer. In some cases, this can happen unintentionally due to a lack of liquid supply, a clogged inlet, or other operational issues. Running a diaphragm pump dry can have varying consequences, depending on the pump's design and construction.

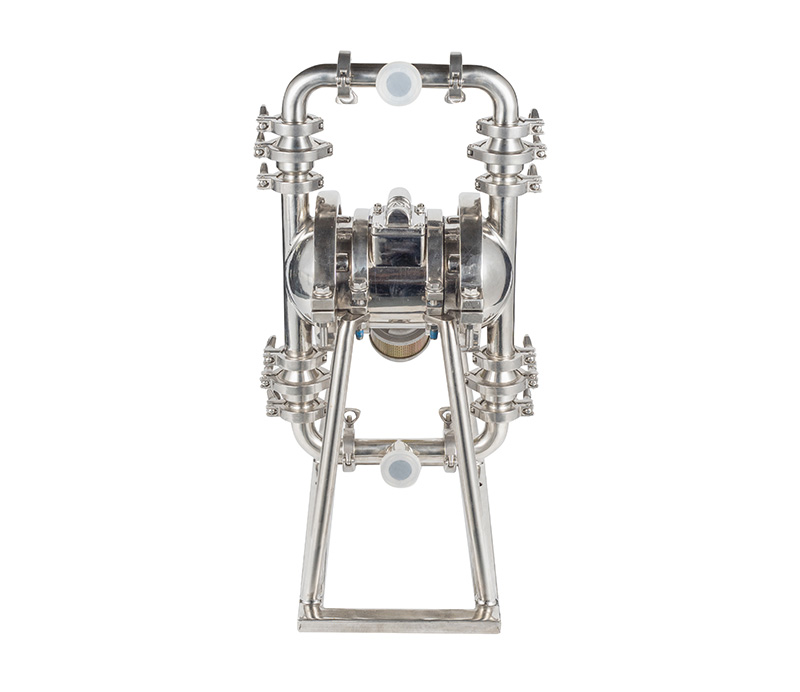

1 Inch Sanitary Pneumatic Diaphragm Pump (FDA)

Impact of Running Dry

Short-Term Effects

Running a diaphragm pump dry for a short duration may not cause immediate damage, especially if the pump is equipped with self-priming capabilities.

However, extended dry running can lead to several issues:

Overheating: Dry running generates heat due to the friction between moving parts. Prolonged dry running can cause the pump to overheat, potentially damaging seals, diaphragms, and other components.

Excessive Wear: The absence of lubrication in the form of pumped fluid can accelerate wear on diaphragms, valves, and seals, affecting the pump's efficiency and lifespan.

Loss of Prime: Prolonged dry running can cause the pump to lose its prime, which makes it difficult to regain the necessary suction for proper operation.

Long-Term Effects

If a diaphragm pump is repeatedly run dry or operated for an extended period without sufficient fluid, the long-term consequences can be severe:

Component Failure: Diaphragms, valves, seals, and other components can deteriorate or fail prematurely due to excessive wear caused by dry running.

Reduced Efficiency: The efficiency of the pump may decline due to worn components, leading to reduced flow rates and increased energy consumption.

Costly Repairs: Continued dry running can result in frequent breakdowns and the need for costly repairs or replacements of essential parts.

Guidelines for Safe Operation

To ensure the optimal lifespan and performance of a diaphragm pump, follow these guidelines:

Monitor Fluid Levels: Regularly check and maintain adequate fluid levels in the pump's reservoir or source to prevent dry running.

Use Anti-Run Dry Devices: Some diaphragm pumps come equipped with anti-run dry devices that automatically shut down the pump when the fluid level is too low. Install Pressure Relief Valves: Pressure relief valves can help prevent overheating and component damage during unexpected dry running events.

Follow Manufacturer's Recommendations: Adhere to the manufacturer's guidelines regarding dry running limitations and maintenance practices. Inspect and Maintain: Regularly inspect and maintain the pump, including diaphragms, valves, and seals, to prevent wear and potential failures.

Conclusion

While diaphragm pumps are designed to handle short periods of dry running, extended or repeated dry running can lead to overheating, excessive wear, and component failure. To ensure the longevity and efficient performance of a diaphragm pump, it's essential to adhere to recommended operating practices, monitor fluid levels, and take preventive measures against running the pump dry. Following these guidelines will help maintain the reliability and effectiveness of diaphragm pumps in various industrial applications.

200

0

0

Comments

All Comments (0)