Unveiling the Power of Mounted Workover Rigs: Revolutionizing Oilfield Operations

In the ever-evolving world of oilfield operations, innovation is the key to efficiency and productivity. One such innovation that has taken the industry by storm is the Mounted Workover Rig. This article will delve into the intricacies of these rigs, exploring their significance, components, operational procedures, and the transformative impact they have on the oil and gas sector.

What is a Mounted Workover Rig?

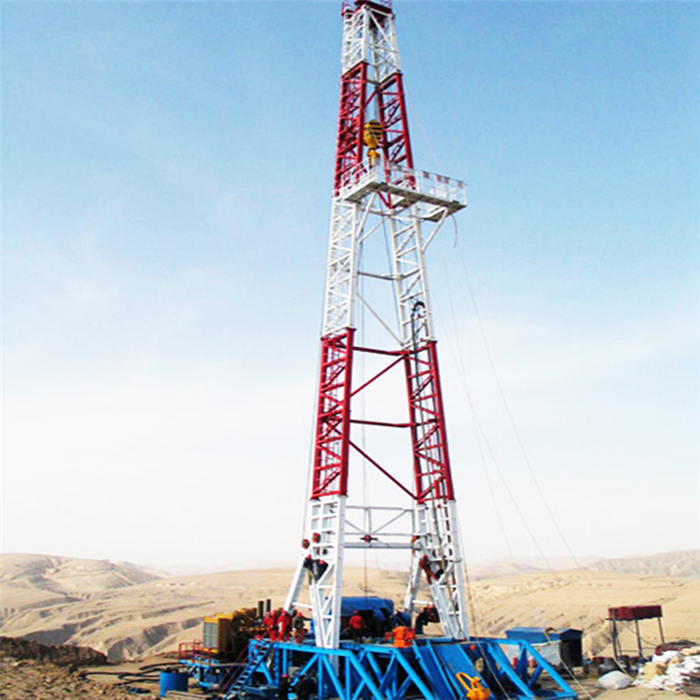

Before we dive deeper into the world of Mounted Workover Rigs, let's establish a fundamental understanding of what they are. A Mounted Workover Rig, often referred to as a "workover unit," is a specialized piece of equipment designed for maintenance and intervention in oil and gas wells. These rigs are mounted on trucks or trailers, making them highly mobile and versatile.

The Anatomy of a Mounted Workover Rig

1. Mast and Derrick

Mounted Workover Rigs are equipped with a sturdy mast or derrick. This towering structure provides the necessary support and stability for various operations.

2. Drawworks

The heart of the rig, the drawworks, is responsible for hoisting and lowering tools and equipment into the wellbore. It operates through a system of cables and pulleys.

3. Power System

Mounted Workover Rigs are powered by engines, typically diesel, which provide the energy required to operate the rig's various components.

4. Control Cabin

A control cabin is where the rig operator manages and monitors the rig's functions. Advanced technology and instrumentation are often found in these cabins.

The Versatility of Mounted Workover Rigs

Mounted Workover Rigs are not confined to a single task. Their versatility shines through in a range of operations, including:

Additional reading:Exploring the Diverse Applications of Gravel Pumps

The Benefits of Custom Bearings

Types of Forklift Attachments

The Core Function of Slurry Pump Impellers

How does a universal joint work?

Which is better CV joints or universal joints?

Where is tyre coupling used?

1. Well Maintenance

Workover rigs are essential for routine maintenance tasks such as cleaning, perforating, and repairing well casings.

2. Plug and Abandonment

When a well reaches the end of its productive life, workover rigs assist in plugging and abandoning it safely and efficiently.

3. Production Enhancement

These rigs are employed to enhance well production, often through methods like hydraulic fracturing and acidizing.

Advantages of Mounted Workover Rigs

1. Mobility

Mounted on Truck Mounted Workover Rig or trailers, these rigs can be easily transported to different well locations, reducing downtime.

2. Cost-Effective

Compared to traditional drilling rigs, workover units are a cost-effective solution for well intervention and maintenance.

3. Environmental Benefits

The precise operations of workover rigs lead to reduced environmental impact, minimizing waste and emissions.

Transforming the Oilfield Landscape

Mounted Workover Rigs have ushered in a new era of efficiency and productivity in the oil and gas industry. Their ability to swiftly adapt to various tasks and their cost-effectiveness have made them indispensable tools for operators worldwide.

Conclusion

As the oil and gas industry continues to evolve, Mounted Workover Rigs stand as a testament to human ingenuity. Their mobility, versatility, and cost-effectiveness have made them a cornerstone of modern well intervention and maintenance. With these rigs at their disposal, oilfield operators can look forward to a future of increased efficiency and reduced environmental impact.

Additional reading:How to Achieve Gear Coupling Reliability

How GIM Revolutionizes Plastic Manufacturing: Advantages and Applications

What Is the Fuel Efficiency of Caterpillar Diesel Engines?

What are the different types of hydraulic check valves?

Are Photocatalyst Filters Safe for Indoor Air Purification?

What are the three types of mechanical seals?

Thermal Expansion of Industrial Aluminum Castings

175

0

0

Related Articles

Comments

All Comments (0)