The basic knowledge introduction of Fiberglass Mesh Filter

Basic Information:

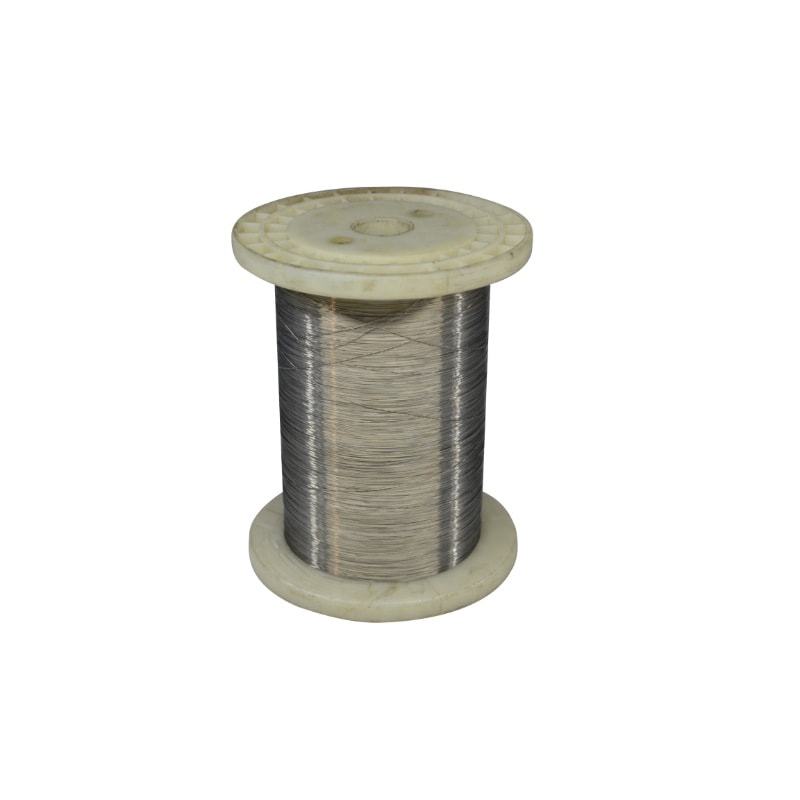

Fiberglass Filter Cloth is weaved by alkali-free E-glass fiberglass yarn, specially developed and used for filtration, turbulence reduction and flow distribution improvement of non‐ferrous alloys especially the molten aluminium. It is used in Vertical Casting Tables and in molten aluminium launder or holding furnace sprue, transferring from ladle to holding furnace etc. Effectively remove the inclusions and aluminum oxide films from molten aluminium liquid.

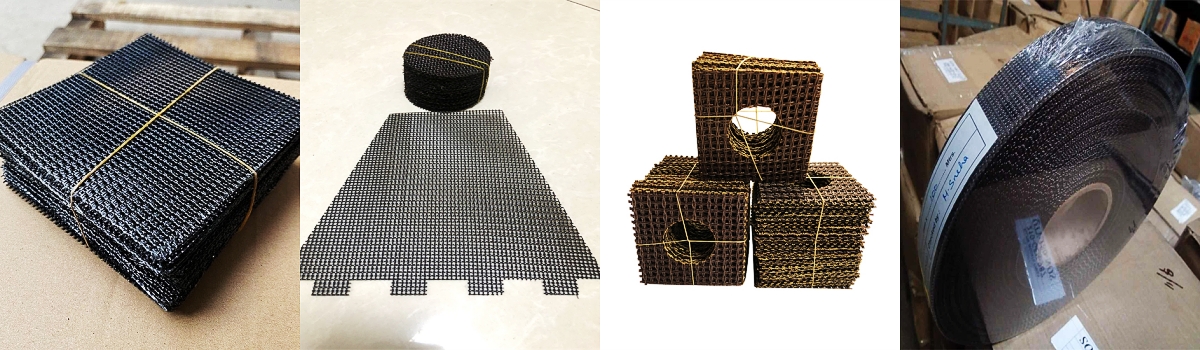

There are two types:

● One is white color and soft without any coating.

● The other is brown color with coating by special resin.

The Shapes Of Fiberglass Mesh Filters:

Fiberglass Mesh Filter can be produced to many kinds of shapes just according to clients' requirements, such as: Square, Rectangle, Round, Fan and other heteroideus.

The Cap Filters:

The cap-style is woven with special high-twist & high-strength alkali-free fiberglass and special post-treatment. The maximum temperature resistance can reach 900 ℃.

Widely used in automobile and motorcycle wheels, cylinder pistons, aluminum rods, aluminum materials, aluminum ingots, aluminum plates and precision casting of all types of aluminum alloy casting.

Unleashing the Power of Hot Rolled Steel Coil: The Secret to Superior Strength

How Do You Specify a Reducing Tee?

The Art of Precision Machining: Exploring the Process of Graphite EDM

Everything You Should Know: Fused Magnesia

A Comprehensive Guide to Aluminum Sheets

What are the advantages of finned tube?

Top 5 Industries Relying on Hot Dipped Galvanized Wire for Durability

Fiberglass Filtration & Shunt Combo bag:

Fiberglass Filtration & Shunt Combo bag is weaved by fiberglass yarn and through special process, its withstand temperature up to 1000 °C.

Apply to filter and evenly distribute molten aluminum in molds.

The Technical Parameters:

| Type | Fiberglass Filter Cloth in roll for aluminum filtration | |

| Yarn type | E-glass fiberglass | |

| Weave type | Leno & plain | |

| Width/roll | 0.9m/1.0m ± 1cm and customized | |

| Length/roll | 100m/150m/200m and customized | |

| Thickness | 0.35-0.6mm | |

| Weight | 150-350g/m2 | |

| Mesh opening | 0.8*0.8/1.0*1.0/1.2*1.2/1.5*1.5/2.0*2.0/2.5*2.5mm and customized | |

| Coating | No Coating | White color and soft fabric |

| Coating with special resin | Brown color and hardness fabric | |

| Work Temperature | 700-900℃ | |

| Softening Temperature | 900℃ | |

| Continuous Working Hours | <20Min.(700-800℃) | |

| Gas Emit | ≤30cm 3/g | |

| Loss on ignition | ≤3% | |

| SiO2 | ≥58% | |

| Certificate | ISO9001:2015 | |

"Hebei Cangchen" Brand

We, Cangchen, a professional foundry filtration products manufacturer with ISO Certificate who focuses on the production, sales, service and solutions. We are the recognized leader in the development and production of casting filters at home and abroad, and possesses the excellent innovation capabilities in filter manufacturing technology.

Since founded in 2002, with excellent quality and continuous design innovation, we have successfully opened the international market, cooperate with a large number of clients all over the world.

Main products include all kinds of high silica fiberglass filter mesh, smokeless & odorless high temperature carbonized fiberglass filtration mesh, fiberglass filter bag and other heteromorphic filter mesh.

All shapes can be customized just according to your own drawings and samples!

Weclome you to inquiry any of our foundry filtration products!

How to Control the Quality of Micro Silica Fume?

Galvanized Steel Coil vs. Galvalume Steel Coil: Which Should You Choose?

Which is better galvanized or Galvalume?

Filtration Using Sintered Metal Filters

What Are Common Wire Nails Used For?

Why has the demand for custom aluminum coils surged?

Aluminum casting vs. steel casting: a comparison of properties

198

0

0

Related Articles

Comments

All Comments (0)