The Benefits of Using 2K Injection Moulding Design in Modern Manufacturing

Aug. 03, 2024

**The Benefits of Using 2K Injection Moulding Design in Modern Manufacturing**.

Have you ever wondered how manufacturers create complex plastic parts in a single process? It is thanks to 2K injection moulding design. Let's dive into the world of this innovative technology and discover its many advantages.

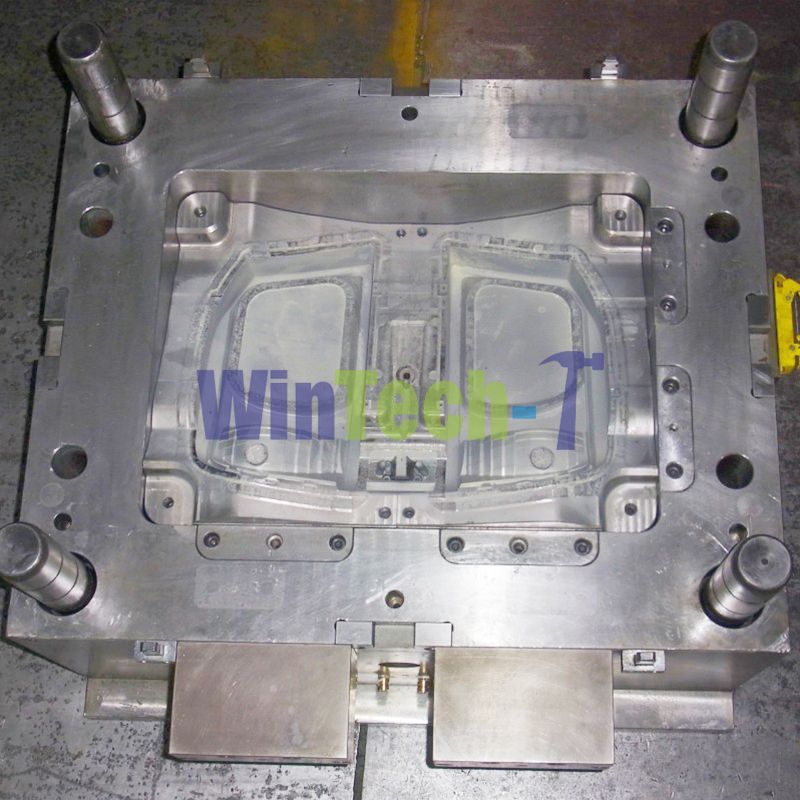

**What is 2K Injection Moulding?**.

"Tell me, what's 2K injection moulding?".

"2K injection moulding, also known as dual-shot moulding, is a process where two different materials are injected into a single mould. This allows manufacturers to create parts with multiple features in one go.".

**Why Choose 2K Injection Moulding?**.

"Why should we switch to 2K injection moulding?".

Here’s why:

1. **Cost Efficiency**.

"You mean we'll save money?".

"Absolutely! By combining two steps into one, this technique reduces labor costs and trash. Fewer moulds mean lower machine costs.".

2. **Superior Product Quality**.

"Is it all about saving money, or do we get better products too?".

"Better products, indeed! 2K injection moulding creates solid, long-lasting components. Think of it, fewer weak spots and smoother finishes mean fewer product returns.".

3. **Complex Designs Made Simple**.

"I've heard it can handle complex shapes. True?".

"True indeed. This process can produce intricate designs that would be difficult with traditional methods. Need multiple colors or materials for your product? No problem!".

**Advantages at a Glance**.

"Can you give me a quick summary of the benefits?".

Sure thing! Here are the key advantages:

1. **Customization**: Achieve unique designs with varied material properties.

.

2. **Durability**: Enhance product strength with dual-material integration.

Additional reading:Key Questions to Ask When Selecting Types of Home Improvement Tools

What Are the Different Types of Tool Holding Devices?

How Many Times Can You Use a Belleville Washer?

Different Types of Lathe Chucks

Features and Benefits of Spherical Hex Nut

How to Choose the Right Roller Bearings for Your Needs

Hexagon Metal Mesh: Applications and Benefits

.

3. **Efficiency**: Reduce production time by combining processes.

.

4. **Consistency**: Produce consistent parts with high precision.

.

5. **Sustainability**: Minimize waste and carbon footprint.

**Applications in Modern Manufacturing**.

"So, where can we use this technology?".

"Good question! 2K injection moulding is versatile, useful in various industries like automotive, electronics, medical devices, and consumer goods.".

**Automotive Industry**.

"Imagine creating a car dashboard with multiple materials for aesthetic and functional purposes. That's possible with 2K injection moulding.".

**Consumer Goods**.

"From toothbrush handles to kitchen gadgets, this technology helps make attractive and durable products.".

**Medical Devices**.

"Precise and hygienic components for medical equipment? Yes, 2K injection moulding delivers just that.".

**Electronics**.

"Think of those sleek, multi-colored phone cases. They owe their beauty to this innovative technology.".

**How to Start Using 2K Injection Moulding?**.

"Wow, I’m sold! How do we start?".

"First, you'd need to consult a 2K injection moulding supplier. They can guide you through the design and production process. Need expert advice? Don't hesitate to contact us!".

In conclusion, 2K injection moulding design is shaking up modern manufacturing with its cost efficiency, superior product quality, and capacity to handle complex designs. If you're a manufacturer's looking to capitalize on these benefits, reaching out to a trusted supplier is a great starting point. Any doubts? Contact us for more information!

Are you interested in learning more about 2k injection moulding design, china plastic moulding supplies supplier, china custom injection moulding? Contact us today to secure an expert consultation!

Additional reading:Advantages and Applications of Thread Bar

What Are The Standards for Anchor Bolts?

A Friendly Guide to Keeping Your Check Valves in Top Shape

Endless Round Slings vs. Chain Slings: Comparing Strength, Durability, and Flexibility

What Are the Common Uses of Domed Nuts?

Choosing the Right Rubber Slurry Pump: A Comprehensive Buyer's Guide

Can You Stack Wave Springs?

58

0

0

Related Articles

Comments

All Comments (0)