Welded Lamination: Exploring the Advancements and Applications

Introduction

Welcome to our comprehensive guide on welded lamination, a cutting-edge technique that has revolutionized the manufacturing industry. In this article, we will delve into the depths of welded lamination, exploring its benefits, applications, and advancements. Whether you're a professional in the field or simply curious about this innovative technology, this article will provide you with valuable insights and detailed information.

Welded Lamination: Understanding the Basics

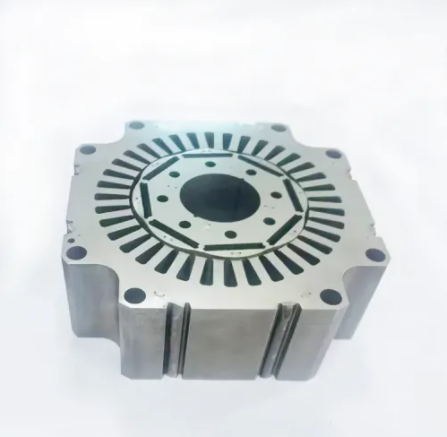

Welded lamination is a process that involves joining multiple layers of material together through precise welding techniques. It is commonly used in industries such as automotive, aerospace, and construction, where the need for strong and durable components is paramount. By bonding multiple layers, welded lamination enhances structural integrity and improves the overall performance of the finished product.

Advancements in Welded Lamination Technology

Over the years, advancements in welded lamination technology have paved the way for new possibilities and improved manufacturing processes. Let's explore some of the notable advancements in this field:

1. Advanced Welding Methods

With the advent of sophisticated welding methods, such as laser welding and friction stir welding, the precision and efficiency of welded lamination have reached new heights. These advanced techniques allow for seamless integration of materials, resulting in stronger and more reliable bonds. Laser welding, in particular, offers high-speed welding with minimal heat input, reducing distortion and ensuring exceptional quality.

2. Materials Innovation

The continuous development of new materials has significantly contributed to the advancement of welded lamination technology. From lightweight alloys to high-strength composites, the availability of diverse materials has expanded design possibilities and improved the performance of the final products. These materials offer enhanced corrosion resistance, superior mechanical properties, and increased durability.

3. Automation and Robotics

Automation and robotics have revolutionized the manufacturing industry, and welded lamination is no exception. With the integration of robotic systems, precise and repeatable welding processes can be achieved, leading to consistent and high-quality laminated structures. Automated welding also reduces the risk of human error, enhances production efficiency, and optimizes resource utilization.

4. Non-Destructive Testing

Non-destructive testing (NDT) methods have advanced significantly, enabling thorough inspection and quality assurance of welded laminations. Techniques such as ultrasonic testing, radiography, and magnetic particle inspection ensure the integrity of the welded joints, detecting any potential defects or discontinuities. These NDT methods provide valuable insights into the structural soundness of laminated components.

Applications of Welded Lamination

Welded lamination finds applications in various industries, offering numerous benefits and opportunities for innovation. Let's explore some key applications where welded lamination excels:

1. Automotive Industry

In the automotive industry, welded lamination plays a crucial role in the production of lightweight and fuel-efficient vehicles. Laminated components, such as body panels, chassis parts, and structural reinforcements, offer improved strength and rigidity while reducing overall weight. This results in enhanced fuel economy, better performance, and increased safety.

2. Aerospace and Defense

The aerospace and defense sectors heavily rely on welded lamination to create robust and reliable structures. Aircraft components, including wings, fuselage sections, and engine parts, benefit from the strength and durability provided by laminated materials. The lightweight nature of laminations also contributes to increased payload capacity and improved fuel efficiency in aerospace applications.

3. Construction and Infrastructure

Welded lamination has found extensive use in the construction and infrastructure industries. From bridges and buildings to pipelines and offshore structures, laminated components offer enhanced load-bearing capabilities and structural integrity. Welded laminations ensure resistance against harsh environmental conditions, seismic forces, and wear, ensuring the longevity of infrastructure projects.

4. Renewable Energy

Renewable energy technologies, such as wind turbines and solar panels, rely on welded laminations for efficient and durable construction. Laminated components enable the production of lightweight and aerodynamic turbine blades, increasing energy capture and reducing maintenance costs. Solar panels benefit from laminated structures that protect delicate photovoltaic cells and enhance overall durability.

Frequently Asked Questions (FAQs)

1. What are the key advantages of welded lamination?

Welded lamination offers several advantages, including enhanced strength, improved structural integrity, and weight reduction. It enables the joining of diverse materials, allowing for innovative designs and improved performance.

2. Is welded lamination suitable for joining dissimilar materials?

Yes, welded lamination excels at joining dissimilar materials with different properties. This capability opens up opportunities for creating hybrid structures with optimized characteristics.

3. How does welded lamination contribute to sustainability?

By reducing material waste, enhancing fuel efficiency, and improving product durability, welded lamination contributes to sustainable manufacturing practices. It enables the creation of lightweight structures that minimize environmental impact.

4. What quality assurance measures are implemented for welded laminations?

Welded laminations undergo rigorous quality assurance processes, including non-destructive testing methods like ultrasonic testing and radiography. These techniques ensure the integrity and reliability of the joined materials.

5. How does automation enhance the efficiency of welded lamination?

Automation and robotics enable precise control and repeatability in the welding process, ensuring consistent quality. It reduces the risk of human error, accelerates production, and optimizes resource utilization.

6. Are there any limitations or challenges associated with welded lamination?

While welded lamination offers numerous benefits, challenges such as process optimization, material compatibility, and cost-effectiveness must be considered. Proper selection of welding methods and materials is crucial for achieving optimal results.

Conclusion

Welded lamination has emerged as a game-changing technology, transforming industries and enabling the production of high-performance components. Through advancements in welding methods, materials innovation, automation, and non-destructive testing, welded lamination has become an indispensable tool for achieving strength, durability, and efficiency in manufacturing. As industries continue to evolve, welded lamination will undoubtedly play a pivotal role in shaping the future of engineering and design.

More info view here.

217

0

0

Comments

All Comments (0)