What are the properties of polypropylene fiber?

Polypropylene fiber possesses several important properties that make it a valuable material for various applications. Some of the key properties of polypropylene fiber include:

Lightweight: Polypropylene is a lightweight material, which is advantageous for applications where weight is a concern, such as in textiles, outdoor gear, and automotive components.

High Strength: Despite its lightweight nature, polypropylene fiber is strong and durable. It has good tensile strength, which makes it suitable for use in ropes, twines, and other load-bearing applications.

Chemical Resistance: Polypropylene is highly resistant to a wide range of chemicals, including acids, bases, and solvents. This property makes it suitable for use in environments where exposure to chemicals is a concern.

Moisture Resistance: Polypropylene is hydrophobic, meaning it repels water. It does not absorb moisture easily, making it a good choice for applications where moisture resistance is important, such as outdoor textiles and marine ropes.

Low Moisture Absorption: Polypropylene has low moisture absorption, which helps it maintain its properties even when exposed to moisture or humidity.

Heat Resistance: Polypropylene has a relatively high melting point, making it resistant to heat. It retains its shape and properties at temperatures below its melting point, which is around 160-170°C (320-338°F).

Colorfastness: Polypropylene fibers are known for their ability to retain color well. They are less prone to fading when exposed to sunlight compared to some other synthetic fibers.

Additional reading:How is EVA Hot Melt Adhesive Applied?

How is Copper Sulphate Used on Plants?

What is HPMC used for in construction?

What is Methylpropiophenone used for?

What is Activated Carbon and How is it Made?

Choosing the Right Hydroxyethyl Methyl Cellulose (MHEC) for Your Needs

What is the difference between Ivomec and Ivermectin?

Hypoallergenic: Polypropylene is non-toxic and hypoallergenic, making it suitable for use in medical and healthcare products such as surgical gowns and face masks.

Good Insulator: It is an excellent electrical insulator, which is advantageous in applications where electrical conductivity is a concern.

Recyclable: Polypropylene is recyclable, and many products made from it can be recycled, reducing environmental impact.

Mold and Mildew Resistance: Due to its resistance to moisture and water absorption, polypropylene is less susceptible to mold and mildew growth.

Abrasion Resistance: Polypropylene fibers have good resistance to abrasion and wear, making them suitable for applications where the material is subjected to friction or rubbing.

Buoyancy: Polypropylene is buoyant in water, making it useful in applications such as life jackets, marine ropes, and buoyancy aids.

These properties make polypropylene fiber a versatile material that can be used in a wide range of industries and applications, from textiles and packaging to construction and automotive components. Its combination of strength, durability, and resistance to various environmental factors makes it a popular choice for many products.

What are the sectors of the cosmetic industry?

CAS 102-97-6: Everything You Need to Know About This Hot Google Topic

4-Methylphenyl: The Surprising Solution for Weight Loss?

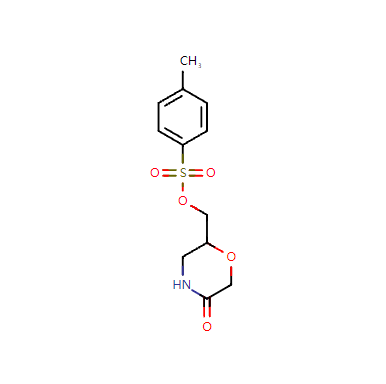

Paxlovid Intermediates: A Breakthrough in Antiviral Drug Manufacturing

Is HPMC natural or synthetic?

What are the different types of pigment powders available?

Unlocking the Potential of HPMC: A Comprehensive Guide to Buying and Utilizing this Versatile Compound

153

0

0

Related Articles

Comments

All Comments (0)