What is the difference between MDPE and HDPE gas pipe?

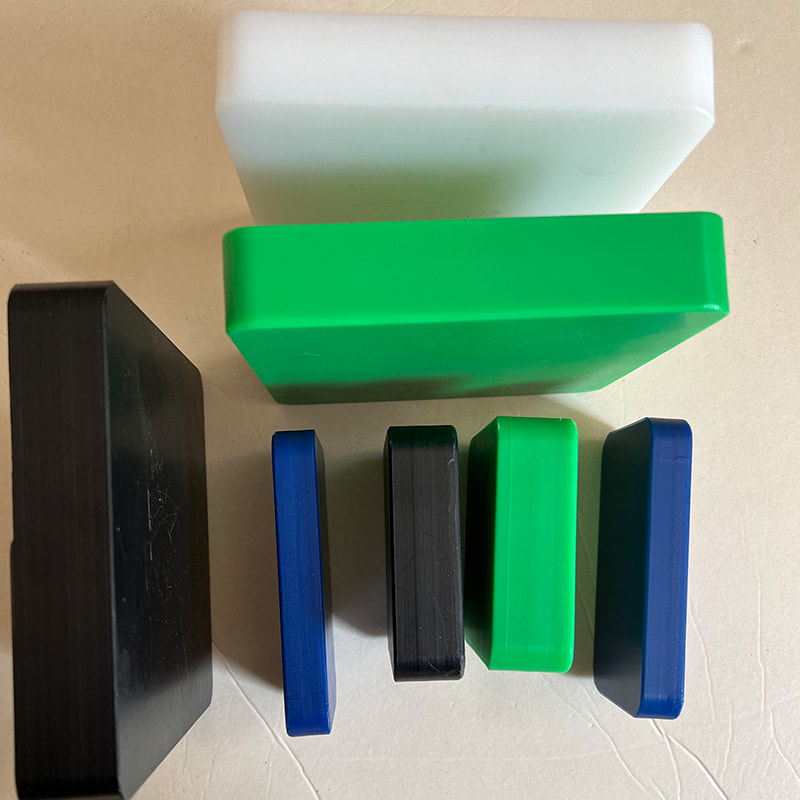

MDPE (Medium-Density Polyethylene) and HDPE (High-Density Polyethylene) are both commonly used materials for gas pipes, but they have some distinct differences in terms of their properties and applications. Here are the key differences between MDPE and HDPE gas pipes:

Density:

MDPE: MDPE stands for Medium-Density Polyethylene, and as the name suggests, it has a medium level of density. MDPE typically has a density range of 0.926 to 0.940 g/cm³.

HDPE: HDPE, or High-Density Polyethylene, has a higher density compared to MDPE. HDPE typically has a density range of 0.941 to 0.965 g/cm³. This higher density gives HDPE greater strength and durability.

Pressure Rating:

MDPE: MDPE pipes are suitable for lower-pressure applications. They are commonly used for natural gas distribution systems, where the pressure requirements are not extremely high.

HDPE: HDPE pipes are designed to withstand higher pressure levels. They are often used for more demanding applications, such as industrial processes or high-pressure natural gas transmission lines.

Flexibility:

MDPE: MDPE pipes are known for their flexibility, which makes them easy to handle and install. This flexibility is especially useful when navigating around obstacles or laying pipes in uneven terrain.

HDPE: HDPE pipes are also flexible but may be slightly less so compared to MDPE. However, they are still more flexible than many other pipe materials like steel or PVC.

Additional reading:The Efficiency and Environmental Benefits of Plastic Crusher Machines

Polypropylene Sheet: A Versatile and Sustainable Solution for Diverse Applications

Benefits of using PE surface protection film

UHMWPE Sheet: The Ultimate Solution for High-Performance Applications

Advantages of Polyurethane Screen Panels in Screening and Separation Processes

What is dredge pipe used for?

How can I ensure the recycled PET flakes I purchase meet industry standards and regulations?

Material Characteristics:

MDPE: MDPE is chosen for gas distribution because of its good resistance to cracking and its ability to withstand the stresses associated with gas flow. It provides a balance between flexibility and strength, making it suitable for typical gas distribution systems.

HDPE: HDPE is known for its exceptional durability and resistance to chemicals, making it suitable for a wide range of applications beyond gas distribution. It is less prone to cracking or brittleness compared to MDPE.

Color Coding:

MDPE: MDPE gas pipes are typically colored yellow, which is a standardized color code in many regions to indicate that the pipe contains natural gas. This helps identify gas lines easily.

HDPE: HDPE pipes may also be yellow when used for gas distribution, but the color coding can vary by region and application.

Regulatory Compliance:

Both MDPE and HDPE gas pipes must meet stringent regulatory standards and undergo testing to ensure they are safe and suitable for their intended applications. Compliance with local and national codes and regulations is crucial for both types of pipes.

In summary, MDPE and HDPE gas pipes are both widely used for gas distribution, but they differ in terms of density, pressure rating, flexibility, and specific applications. MDPE is often used for lower-pressure distribution systems, while HDPE is chosen for higher-pressure applications or situations requiring increased durability. The choice between MDPE and HDPE depends on the specific needs of the gas distribution system and regulatory requirements in a particular region.

What are Types and Applications of Conveyor Belts?

What is an Industrial Hose?

Advantages of Silicone Sealing Valves

Key Considerations When Choosing Rubber Stoppers

Everything You Need to Know About PVC Drainage Pipe

What Is High Density Polyethylene Pipe?

RPET Material – 10 Frequently Asked Questions

175

0

0

Related Articles

Comments

All Comments (0)