Welding Precision: Using Pipe Pinching Rotators for Seamless Pipeline Construction.

The construction of pipelines is a complex and critical process, requiring precision, efficiency, and safety. In recent years, the welding industry has witnessed a significant advancement with the introduction of innovative tools like Pipe Pinching Rotators. These rotators have revolutionized the way pipelines are constructed, ensuring seamless and high-precision welding.

The Role of Pipe Pinching Rotators:

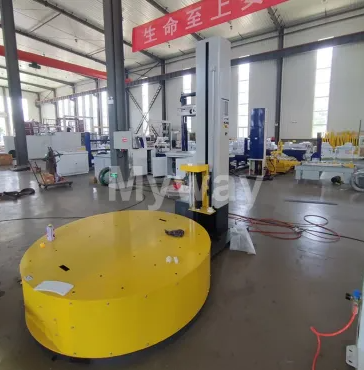

Pipe Pinching Rotators, also known as Pipe Turning Rolls, are specialized tools designed to support the welding process by rotating and positioning large and heavy pipes. They are commonly used in various pipeline construction projects, including oil and gas pipelines, water pipelines, and more. The key features of these rotators include:

Load-Bearing Capacity: Pipe Pinching Rotators can handle pipes of varying sizes and weights, ensuring stability and safety during the welding process.

Precise Positioning: The rotators allow for controlled rotation and positioning of pipes, enabling welders to access all angles and weld joints with ease.

Safety Measures: These tools are equipped with safety features to prevent pipe slippage, reduce the risk of accidents, and protect both the equipment and personnel.

Advantages of Pipe Pinching Rotators in Pipeline Construction:

Seamless Welding: The controlled rotation of pipes ensures that welders have easy access to every part of the pipe, resulting in high-quality, continuous welds.

Efficiency: Pipe Pinching Rotators significantly reduce the time and labor required for welding, leading to faster project completion and cost savings.

Understanding the Working Principle of Continuous Inkjet Printers

What Are The Applications of Electric Wheel Loaders?

How Do Chairlifts Stay on Cable?

How do you use a paper die-cutting machine?

Carton Clamp: Is it the Ultimate Solution for Efficient Warehouse Management?

Advantages of Lithium Battery Laser Welding Machines

Characteristics and Main Uses of Oil-Resistant Conveyor Belts

Safety: These tools enhance safety by minimizing the manual handling of heavy pipes and reducing the risk of accidents.

Reduced Material Waste: Precise welding with rotators minimizes material waste and the need for rework, making pipeline construction more environmentally friendly.

Versatility: Pipe Pinching Rotators are versatile and can be used in various pipeline construction applications, ensuring adaptability to project-specific requirements.

Applications in Pipeline Construction:

Oil and Gas Pipelines: Pipe Pinching Rotators are crucial in the construction of oil and gas pipelines, where the quality and integrity of welds are of paramount importance.

Water and Sewer Pipelines: These rotators play a vital role in the construction of water and sewer pipelines, ensuring that they are structurally sound and reliable.

Industrial Piping: In industrial settings, these tools are used to construct pipelines for conveying fluids, chemicals, and other materials.

Pipe Pinching Rotators have transformed the pipeline construction industry by providing a precise, efficient, and safe solution for welding large pipes. Their ability to ensure seamless welds, reduce material waste, and enhance overall project efficiency has made them an indispensable tool in the pipeline construction process. As the demand for pipelines continues to grow, these rotators will continue to play a significant role in ensuring the integrity and reliability of our infrastructure.

Is a Tea Packing Machine Your Cup of Tea?

Do ozone generators work in cars?

Is ozone water treatment safe?

What is a Closed Cooling Tower?

When to Replace Brake Pads?

Differences Between Thrust Spherical Roller Bearings and Other Bearing Types

What are 5 operations that can be performed on a CNC lathe?

105

0

0

Comments

All Comments (0)